24-HOUR EMERGENCY LINE: 1-844-808-4904

150

MMCF/D sour gas processing capacity

10,000

BBL/D NGL and condensate handling

370

tonnes/day sulfur recovery

CAPABILITIES

Where Albright fits in

Located near Grande Prairie, Albright anchors CSV’s network in one of Alberta’s busiest producing regions. Designed to serve multiple producers, it includes sour gas treatment, liquids recovery, and the province’s first new natural gas plant with sulfur recovery in three decades.

Developed as a greenfield project and executed entirely by CSV’s own team, Albright reflects the company’s integrated model from design through operations.

The facility establishes new technical benchmarks for efficiency, safety, and emissions control, while providing long-term processing capacity for regional producers.

Its scale and configuration strengthen CSV’s ability to support growth across the Montney and demonstrate how modern midstream infrastructure can deliver both reliability and regional benefit.

Sulfur recovery

First new greenfield natural gas plant with sulfur recovery in Alberta in 30 years, utilizing high efficiency SmartSulf technology to achieve top-tier sulfur recovery

Multi-customer design

Developed to serve a range of producers, offering flexibility in how gas is processed and handled

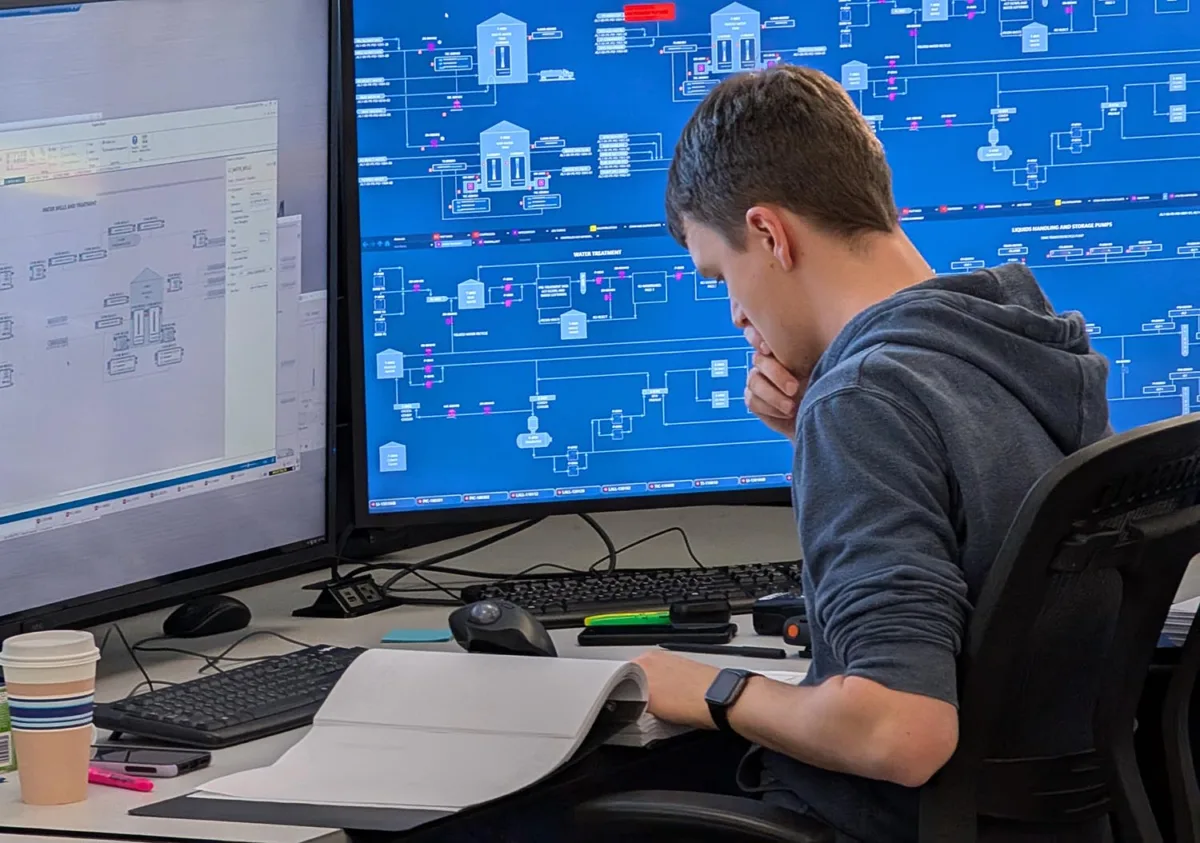

Advanced operations

Technology and processes developed to maximize uptime and operational resilience

Integrated execution

Engineered and built by CSV’s own team from start to finish

Liquids handling

Hydrocarbon liquid handling designed for 1065 m³/d of liquid hydrocarbons and 636 m³/d of water with connections for third-party water disposal and into the Pembina Peace pipeline system

Compression & refrigeration

Mechanical refrigeration unit capable of -35°C, producing C3/C4 NGL and C5+ products, with total installed process compression of 16,125 HP.

STRATEGIC VALUE

A cornerstone of CSV’s growth strategy

Albright’s scale and location strengthen CSV’s presence in a highly active region of the Montney fairway where producers are investing significant capital.

The project shows that a midstream company of CSV’s size can deliver technically complex infrastructure when few others are building.

ALBRIGHT

A portion of Albright’s annual revenue supports the Creating Shared Value Fund, which directs resources to community projects in the County of Grande Prairie. Combined with local employment and supplier opportunities, Albright’s impact extends beyond energy production into lasting community benefit.